After a lengthy regulatory process, the California Public Utilities Commission (CPUC), on July 25, 2013, approved a series of needed upgrades to San Jose Water Company’s (SJWC) Montevina Water Treatment Plant (Montevina WTP). The final decision approved a settlement between SJWC and the CPUC’s Division of Ratepayer Advocates. Key terms of the settlement require the costs of the project to be included in SJWC’s rate base through the filing of annual advice letters and total project costs to be limited to $62 million. SJWC may request additional funding if project costs exceed the $62 million cap.

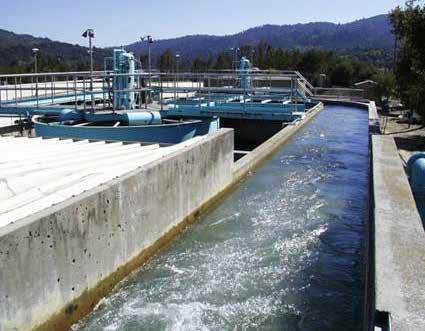

The Montevina WTP is the primary supply source for the Town of Los Gatos and surrounding communities, producing an average of 10 percent of the total supply for Silicon Valley’s largest water retailer. The plant treats local precipitation collected in the Santa Cruz Mountains watershed where a series of dams and automated intakes collect water from local creeks and from water released from SJWC’s reservoirs.

The Montevina WTP, originally commissioned in 1970, has a hydraulic capacity of 30 million gallons per day. Although several upgrades have been made to the plant since that time, the treatment process – direct filtration and chlorination – remains unchanged. State and federal regulatory requirements for sediment and particle (turbidity) removal, disinfection and disinfection byproducts have become significantly more stringent since 1970. Additionally, SJWC has historic water rights on Los Gatos Creek and its tributaries, and limitations in the existing treatment process often result in loss of this low cost water supply.

In 2008, SJWC prepared a Facilities Plan to evaluate and recommend the necessary process and infrastructure upgrades for the Montevina WTP. The Facilities Plan served as the key document in SJWC’s September 2010 application to the CPUC seeking approval of project costs and recovery for plant upgrades to meet water quality regulations and maximize use of the local water supply. Microfiltration (MF) membrane technology was ultimately chosen after evaluating the water quality data, regulatory drivers and condition of the infrastructure as well as pilot testing available technologies. MF was selected because of its ability to effectively remove turbidity while requiring lower disinfection for eliminating pathogens. Also, the technology’s compact footprint is key to constructing upgrades on the small site. SJWC’s experience with MF technology dates back to 1994 when the company commissioned the first full-scale MF plant in the United States at its Saratoga WTP.

Preparations are well underway to move the project forward. In addition to using state-of-the-art treatment technology, SJWC also is employing a progressive design-build project delivery method.

The small, constrained plant site, combined with the need to control costs, streamline the time to completion and operate the existing plant during construction, led to selecting this method. Progressive design-build offers the advantages of having a single point of contact for the owner, involving the construction team early in the design process and allowing greater input by SJWC in process-design decisions. The company anticipates awarding the progressive design-build contract to one of three prequalified teams by the end of 2013.

“This decision by the CPUC is really a win-win for our customers” stated Palle Jensen, Senior Vice President of SJWC. “In addition to new water quality regulations, Montevina is currently challenged by aging infrastructure. Many of its key components are at or beyond their useful lives, and the concrete structures do not meet current structural or seismic standards. Additionally, SJWC’s other water supplies are highly dependent on the fragile Sacramento Delta. Therefore, maximizing the use of a low cost, gravity fed supply from the local watershed, as we will be able to do once the Montevina upgrades have been completed, is a tremendous benefit to our customers.”